Iplastiki yeplastiki isetyenziswa rhoqo kushishino lweplastiki yanamhlanje kuba ifumaneka lula kwaye kulula ukusebenza nayo.Inkqubo yeplastiki ye-extrusion ibandakanya ukunyibilika kwezinto zeplastiki, ukunyanzeliswa kwi-die ukuze uyimise kwiprofayili eqhubekayo, kwaye emva koko uyinqumle ubude.Inkqubo lukhetho olulungileyo lwezicelo ezifuna imveliso yokugqibela enecandelo elinqamlezayo elingaguqukiyo.Iindleko eziphantsi kunye namazinga aphezulu emveliso ayenza ibe yinto eqhelekileyo yokuvelisa iimveliso ezifana nemibhobho, iplastiki yamaphepha, ukuhluthwa kwemozulu, ukugquma ucingo kunye neteyiphu yokuncamathelisa.

IiMpahla zePlastiki zeExtrusion

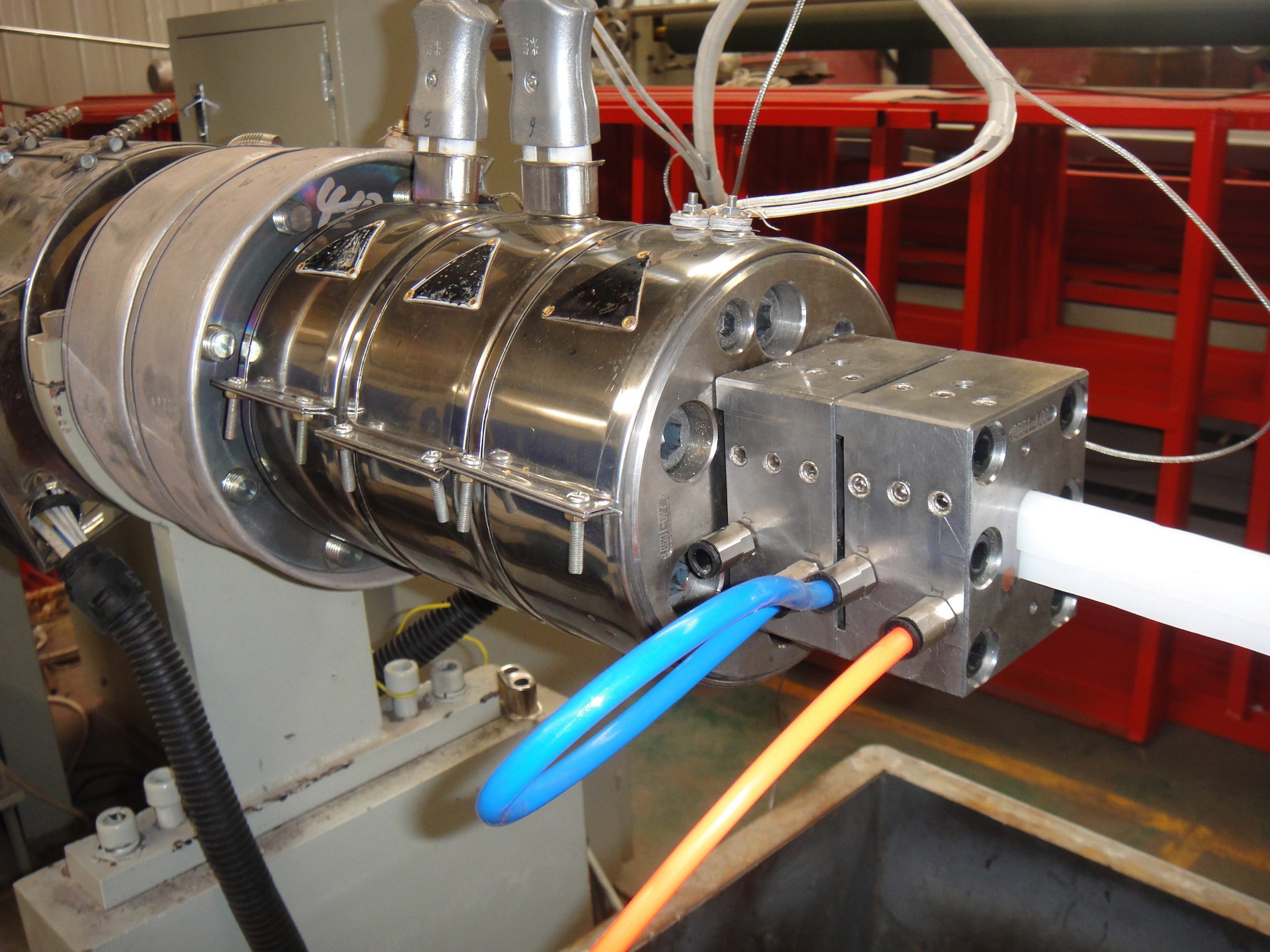

Ngaphambi kokuba kuqaliswe inkqubo yokukhutshwa kweplastiki, kufuneka kufunyanwe oomatshini abafanelekileyo kunye nokubonelela, ngokukodwa umatshini weplastiki okhuphayo.Esi sixhobo ngumatshini olula ngokufanelekileyo oququzelela inkqubo ye-extrusion ukusuka ekuqaleni ukuya ekugqibeleni.Amacandelo aphambili e-extruder yeplastiki abandakanya i-hopper, i-barrel, i-screw drive kunye ne-screw drive motor.

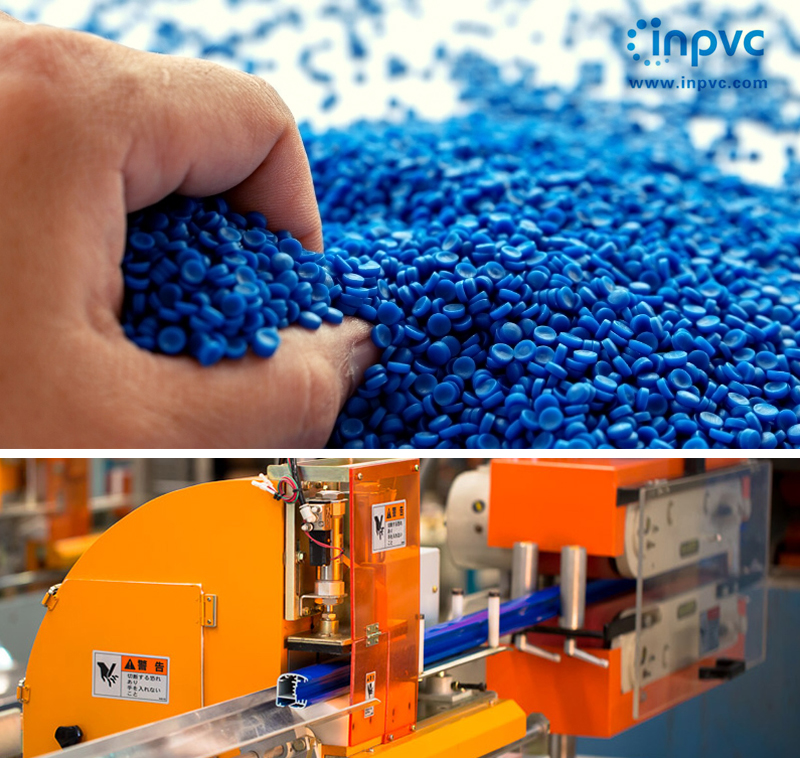

Inxalenye yesibini ebaluleke kakhulu yinto eluhlaza ye-thermoplastic ejoliswe kwi-extrusion.Uninzi lwemisebenzi ye-extrusion ixhomekeke kwiplastiki ye-resin (amaso amancinci amancinci) ukuvumela ukulayishwa okulula kunye namaxesha okunyibilika ngokukhawuleza.Izinto zeplastiki eziqhelekileyo ezisetyenziswe kwinkqubo yokukhupha ziquka i-polystyrene ephezulu (HIPS), i-PVC, i-polyethylene, i-polypropylene, kunye ne-ABS.

Icandelo lokugqibela eliyimfuneko kwi-extrusion yeplastiki kukufa.Idayi lisebenza njengongundo lweplastiki-kwiplastiki ekhutshiweyo, iyafa ivumela ukuhamba nokuhamba kweplastiki etyhidiweyo.Ukufa ngokuqhelekileyo kufuneka kwenziwe ngokwesiko kwaye kunokufuna ixesha elongezelelweyo lokukhokela ngaphambi kokuqala inkqubo yokuvelisa.

IiNkqubo zePlastiki eziKhethekileyo zokuKhupha

Izicelo ezininzi zibiza iinkqubo ezikhethekileyo ze-extrusion ukufumana iziphumo ezaneleyo okanye ukukhawulezisa inkqubo yokuvelisa.Iinkqubo eziqhelekileyo ezikhethekileyo ze-extrusion ziquka:

●Ifilimu evuthelweyo extrusion:Isetyenziselwa ukwenza iimveliso zefilimu zeplastiki ezifana negrosari kunye neengxowa zokugcina ukutya. I-dies kule nkqubo ibonisa uyilo oluthe tye, oluyicylindrical olutsalela iplastiki etyhidiweyo phezulu njengoko isenza kwaye ipholisa.

●Co-extrusion:Iimaleko ezininzi zikhutshiwe ngaxeshanye.Ii-extruders ezimbini okanye ngaphezulu zondla iintlobo ezahlukeneyo zeplastiki kwintloko enye ye-extrusion.

●Ijacket ngaphezulu:I-Extrusion isetyenziselwa ukwambathisa into kwiplastiki ekhuselayo.Iingcingo zangaphandle kunye nejacket yekhebula yeyona ndlela iqhelekileyo yokusetyenziswa kwe-overjacketing.

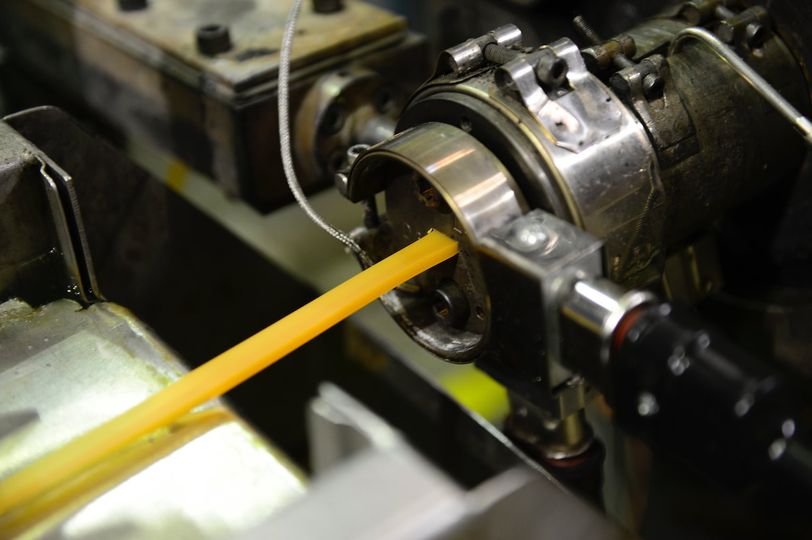

●I-tubing extrusion:Ngokufana extrusion zemveli, ngaphandle die ibandakanya izikhonkwane zangaphakathi okanye mandrels ukuba lula ukuveliswa kwemathiriyeli zeplastiki umngxuma.

Inkqubo eSisiseko yePlastiki Extrusion

Inkqubo yeplastiki ye-extrusion iqala ngokubeka i-resin eluhlaza kwi-hopper ye-extruder.Ukuba i-resin ayinazo izongezo eziyimfuneko kwisicelo esithile (njenge-UV inhibitors, i-anti-oxidants, okanye i-colorants), ngoko zongezwa kwi-hopper.Nje ukuba isendaweni, i-resin idla ngokutyiswa ngomqala wombhobho we-hopper ukuya kumbhobho we-extruder.Ngaphakathi kombhobho kukho isikrufu eside, esijikelezayo esondla intlaka phambili emgqomeni ukuya kwidiyizi.

Njengoko i-resin ihamba phakathi komgqomo, iphantsi kobushushu obuphezulu kakhulu ide iqalise ukunyibilika.Ngokuxhomekeke kuhlobo lwe-thermoplastic, amaqondo obushushu emgqomo anokuba phakathi kwe-400 kunye ne-530 degrees Fahrenheit.Uninzi lwe-extruder's lunomphanda onyuka ngokuthe ngcembe kubushushu ukusuka ekupheleni kokulayisha ukuya kumbhobho wesondlo ukuvumela ukunyibilika kancinci kunye nokunciphisa ukuba nokwenzeka kokuthotywa kweplastiki.

Emva kokuba iplastiki etyhidiweyo ifikelele ekupheleni kombhobho, inyanzeliswa ngepakethi yesikrini kwaye idliwe kumbhobho wesondlo okhokelela ekufeni.Isikrini, esomelezwa yiplate ye-breaker ngenxa yoxinzelelo oluphezulu kwi-barrel, isebenza ukususa ukungcola okunokuthi kubekho kwiplastiki etyhidiweyo.I-porosity yesikrini, inani lezikrini, kunye nezinye izinto zinokuguqulwa de kube ukunyibilika okufanayo kwenzeka ngenxa yexabiso elifanelekileyo loxinzelelo lwangasemva.

Kanye kumbhobho wesondlo, isinyithi esinyibilikisiweyo sifakwe kwi-death cavity, apho ipholisa kwaye iqine.Ukukhawulezisa inkqubo yokupholisa, iplastiki esanda kwenziwa ifumana ibhafu yamanzi etywiniweyo.Kwimeko ye-extrusions ye-plastic sheeting, imiqulu yokupholisa ithatha indawo yokuhlamba amanzi.

Ixesha lokuposa: Oct-25-2021